Introduction

In the tricky world of electronics, wire bonding stands as a pivotal manner for opening electrical connections among semiconductor devices. As science advances, making sure the reliability and effectivity of twine bonding procedures has turn out to be paramount. This article delves into the comprehensive research of wire bonding screw ups, providing insights into techniques, resources, and exceptional practices that mavens can rent to maintain in opposition to viable pitfalls within the twine bonding process.

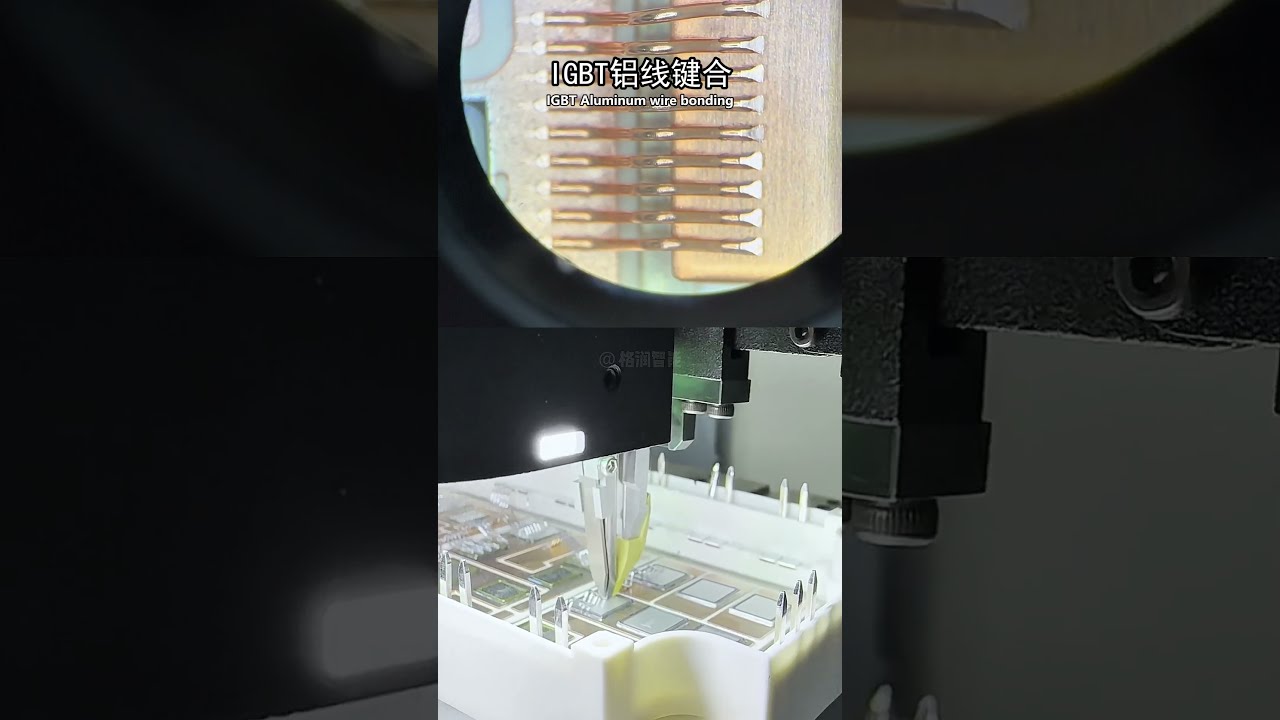

Wire bonding seriously is not just a realistic challenge; it’s an amalgamation of precision engineering and stepped forward technological know-how. Whether you’re facing gold cord bonding, aluminum wire bonding, or exploring the nuances of ribbon and wedge bonding ways, figuring out the intricacies concerned in undertaking mighty cord bonding failure diagnosis is most important.

What is Wire Bonding?

Wire bonding is a strategy used to glue microelectronic components simply by thin wires. This method serves because the spine for respectable electrical connections in a good number of packages ranging from purchaser electronics to automotive techniques. In essence, it comes to due to a wire bonding machine that employs heat and pressure to create metallic bonds among wires and pads on semiconductor chips.

The Wire Bonding Process: An Overview

The twine bonding process encompasses several integral steps:

Preparation: The surfaces should be sparkling and unfastened from illness for greatest bond caliber. Placement: The twine is positioned adequately utilizing really good kit. Bonder Activation: Heat and ultrasonic potential are implemented to create a bond. Loop Formation: A loop is shaped to deal with thermal growth. Finalization: The bond is inspected for integrity.Understanding those Additional resources steps enables engineers recognize where screw ups may possibly appear throughout the time of production.

Conducting Effective Wire Bonding Failure Analysis

When it comes to making certain reliability in cord bonding, reading screw ups will become essential. Failures can stand up as a consequence of various factors adding package malfunctions, material inconsistencies, or environmental stipulations affecting the bonds’ integrity.

Types of Wire Bonding Techniques

- Ball Bonding Wedge Bonding Ribbon Bonding

Each process has its own set of reward and downsides relying at the software—whether or not it is for top-frequency programs or mighty automobile electronics.

Key Factors Influencing Wire Bonding Reliability

Material Selection: Gold vs aluminum can radically impression functionality. Bonding Parameters: Temperature, drive, and time have to be optimized. Environmental Controls: Humidity and contamination degrees play necessary roles in bond electricity.This phase will element how those factors contribute to useful wire bonds or skills screw ups.

Common Causes of Wire Bonding Failures

Understanding standard failure modes is needed for tremendous research:

- Bond Lifting: Often because of inadequate force or temperature settings. Heel Cracking: Typically consequences from thermal tension all the way through operation. Incomplete Bonds: Can stem from improper equipment calibration or deficient drapery high-quality.

These points needs to be absolutely investigated as a result of trying out methodologies like pull tests or shear tests to check their root causes effectively.

Wire Bond Inspection Techniques

Effective inspection programs kind an primary component to any wire bonding failure diagnosis approach:

Visual Inspection

Visual inspections function the 1st line of defense towards defects. Trained body of workers consider bond satisfactory with the aid of magnification tools to spot irregularities including incomplete bonds or foreign debris.

Automated Inspection Systems

Automated strategies leverage complicated imaging technology to come across anomalies instantly:

- X-ray inspection Acoustic microscopy Optical inspection systems

These applied sciences deliver more appropriate assessments compared to handbook inspections.

FAQ Section

What are the maximum universal ingredients used in cord bonding?

Most almost always used fabrics contain gold, aluminum, copper, and silver wires relying on elements like price and alertness specifications.

How does temperature impression wire bonding?

Temperature performs a valuable role; too top can intent destroy at the same time as too low also can cause weak bonds. It's basic that parameters are optimized based totally on one of a kind supplies being bonded.

Can I operate non-harmful testing on cord bonds?

Yes! Non-detrimental checking out methods which includes X-ray inspection will let you test bond integrity without destructive the element itself.

What need to I do if I suspect a failure in my wire bonds?

If you think disasters, conduct thorough inspections simply by each visible tactics and automated strategies sooner than troubleshooting your strategy parameters or apparatus settings.

How steadily deserve to I investigate my cord bonds?

Regular inspections should still be element of your pleasant keep watch over course of; after each creation run or batch can lend a hand catch considerations early on in the past they improve into larger trouble.

What are some best possible practices for making improvements to bond exceptional?

Ensuring cleanliness to your atmosphere, most commonly calibrating tools, classes employees thoroughly, and following standardized tactics can significantly increase total bond nice.

Conclusion

Conducting high quality cord bonding failure analysis requires an know-how of both technical data distinctive to a large number of kinds of bondings—corresponding to ball vs wedge—and broader sides like tools management and environmental controls. By utilising rigorous inspection programs along thorough skills of average failure modes, professionals can anticipate possible problems prior to they translate into construction losses.

Through this article's insights into the complexities surrounding cord bonding know-how—from processes like ribbon bonding in continual modules to exploring the results of gold vs aluminum—it’s transparent that staying advised about business trends is central for good fortune during this domain. With continuous improvements shaping the destiny landscape of electronics manufacturing, embracing innovation although adhering to most efficient practices will pave the approach towards accomplishing more desirable reliability in twine bonded connections throughout all sectors.

This article offers an in depth assessment whereas supplying actionable insights into carrying out triumphant cord bonding failure prognosis inside of innovative digital production landscapes—making sure readers are smartly-capable with competencies perfect throughout plenty of fields inside of this dynamic trade sphere.