Introduction

In the elaborate international of electronics, wire bonding stands as a pivotal process for organising electrical connections between semiconductor devices. As science advances, ensuring the reliability and efficiency of twine bonding approaches has grow to be paramount. This article delves into the finished analysis of cord bonding screw ups, presenting insights into tactics, methods, and top practices that authorities can hire to take care of against advantage pitfalls within the cord bonding strategy.

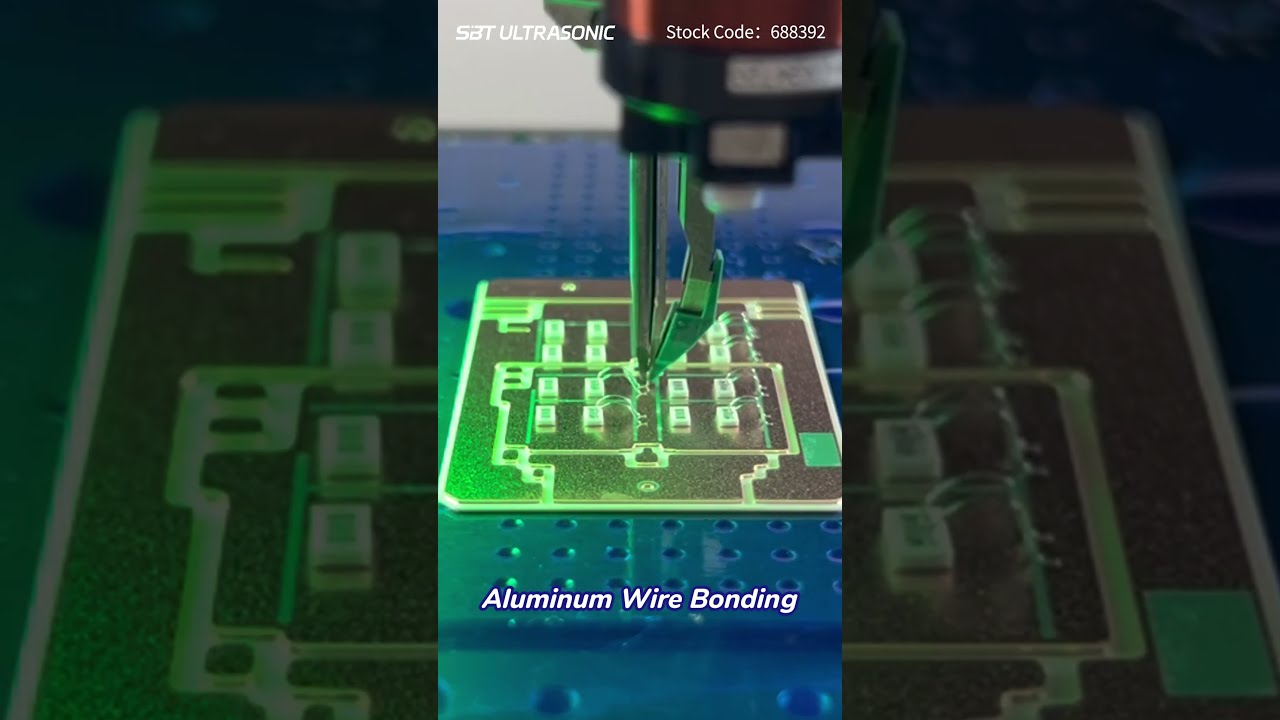

Wire bonding will not be just a useful project; it’s an amalgamation of precision engineering and developed expertise. Whether you’re managing gold twine bonding, aluminum twine bonding, or exploring the nuances of ribbon and wedge bonding options, expertise the intricacies concerned in engaging in efficient cord bonding failure research is essential.

What is Wire Bonding?

Wire bonding is a technique used to attach microelectronic additives as a result of skinny wires. This approach serves because the backbone for reputable electric connections in a lot of purposes ranging from client electronics to automobile methods. In essence, it comprises utilising a wire bonding machine that employs warm and stress to create steel bonds between wires and pads on semiconductor chips.

The Wire Bonding Process: An Overview

The wire bonding process encompasses countless necessary steps:

Preparation: The surfaces have got to be fresh and unfastened from infection for foremost bond exceptional. Placement: The cord is situated accurately driving specialized apparatus. Bonder Activation: Heat and ultrasonic energy are implemented to create a bond. Loop Formation: A loop is formed to house thermal growth. Finalization: The bond is inspected for integrity.Understanding those steps allows engineers identify the place disasters may ensue for the time of manufacturing.

Conducting Effective Wire Bonding Failure Analysis

When it comes to making certain reliability in wire bonding, studying screw ups will become valuable. Failures can rise up because of various factors which include device malfunctions, materials inconsistencies, or environmental conditions affecting the bonds’ integrity.

Types of Wire Bonding Techniques

- Ball Bonding Wedge Bonding Ribbon Bonding

Each methodology has its possess set of benefits and downsides based on the application—regardless of whether it really is for excessive-frequency purposes or strong automobile electronics.

Key Factors Influencing Wire Bonding Reliability

Material Selection: Gold vs aluminum can vastly effect functionality. Bonding Parameters: Temperature, strain, and time would have to be optimized. Environmental Controls: Humidity and infection stages play crucial roles in bond power.This part will element how these aspects contribute to valuable twine bonds or competencies mess ups.

Common Causes of Wire Bonding Failures

Understanding overall failure modes is relevant for robust analysis:

- Bond Lifting: Often as a result of insufficient strain or temperature settings. Heel Cracking: Typically effects from thermal stress for the period of operation. Incomplete Bonds: Can stem from fallacious desktop calibration or negative materials fine.

These things have to be wholly investigated via checking out methodologies like pull checks or shear exams to examine their root causes accurately.

Wire Bond Inspection Techniques

Effective inspection ideas model an mandatory component to any wire bonding failure prognosis method:

Visual Inspection

Visual inspections serve as the 1st line of safeguard in opposition t defects. Trained workforce review bond satisfactory using magnification gear to spot irregularities inclusive of incomplete bonds or foreign particles.

Automated Inspection Systems

Automated methods leverage evolved imaging applied sciences to come across anomalies briskly:

- X-ray inspection Acoustic microscopy Optical inspection systems

These technology deliver greater appropriate assessments compared to guide inspections.

FAQ Section

What are the such a lot regular materials used in twine bonding?

Most mainly used ingredients encompass gold, aluminum, copper, and silver wires based on components like cost and application specifications.

How does temperature impact cord bonding?

Temperature performs a quintessential function; too top can result in break when too low may just result in weak bonds. It's indispensable that parameters are optimized structured on distinctive supplies being bonded.

Can I participate in non-unfavorable trying out on wire bonds?

Yes! Non-negative trying out tips which include X-ray inspection enable you ascertain bond integrity with no amtech Processes damaging the component itself.

What must always I do if I suspect a failure in my cord bonds?

If you watched screw ups, conduct thorough inspections applying the two visual tips and automated approaches until now troubleshooting your system parameters or gear settings.

How more often than not should I look at my twine bonds?

Regular inspections could be portion of your great management course of; after each manufacturing run or batch can help capture worries early on before they increase into increased problems.

What are some choicest practices for recuperating bond first-class?

Ensuring cleanliness on your surroundings, in general calibrating system, working towards group of workers thoroughly, and following standardized approaches can vastly beef up general bond nice.

Conclusion

Conducting mighty twine bonding failure evaluation calls for an knowing of the two technical info exceptional to a large number of sorts of bondings—akin to ball vs wedge—and broader aspects like equipment leadership and environmental controls. By using rigorous inspection tips along thorough awareness of regularly occurring failure modes, authorities can anticipate plausible considerations until now they translate into production losses.

Through this article's insights into the complexities surrounding wire bonding technological know-how—from innovations like ribbon bonding in vigor modules to exploring the results of gold vs aluminum—it’s clean that staying proficient approximately trade trends is principal for luck on this area. With continuous developments shaping the future panorama of electronics production, embracing innovation when adhering to most efficient practices will pave the means closer to reaching enhanced reliability in twine bonded connections throughout all sectors.

This article offers an intensive overview whereas proposing actionable insights into undertaking constructive wire bonding failure analysis within brand new digital manufacturing landscapes—guaranteeing readers are neatly-able with capabilities applicable across plenty of fields inside of this dynamic market sphere.