Introduction

In the evolving global of electronics, the alternative of substances plays a pivotal position in settling on the functionality and reliability of devices. Among a good number of interconnection systems, wire bonding stands proud as a very important manner used to determine electric connections inside semiconductor applications and different digital method. This article delves into an in-depth assessment among copper and silver twine bonding, exploring their homes, advantages, disadvantages, and programs. By the stop of this complete assist, you can actually have a clearer information of which cord bonding system is perfect to your precise desires.

Copper vs Silver Wire Bonding: Which is Right for You?

The debate surrounding copper vs silver twine bonding has been ongoing inside the semiconductor enterprise. Each fabric affords exact reward and disadvantages, affecting the whole thing from check to performance.

What is Wire Bonding?

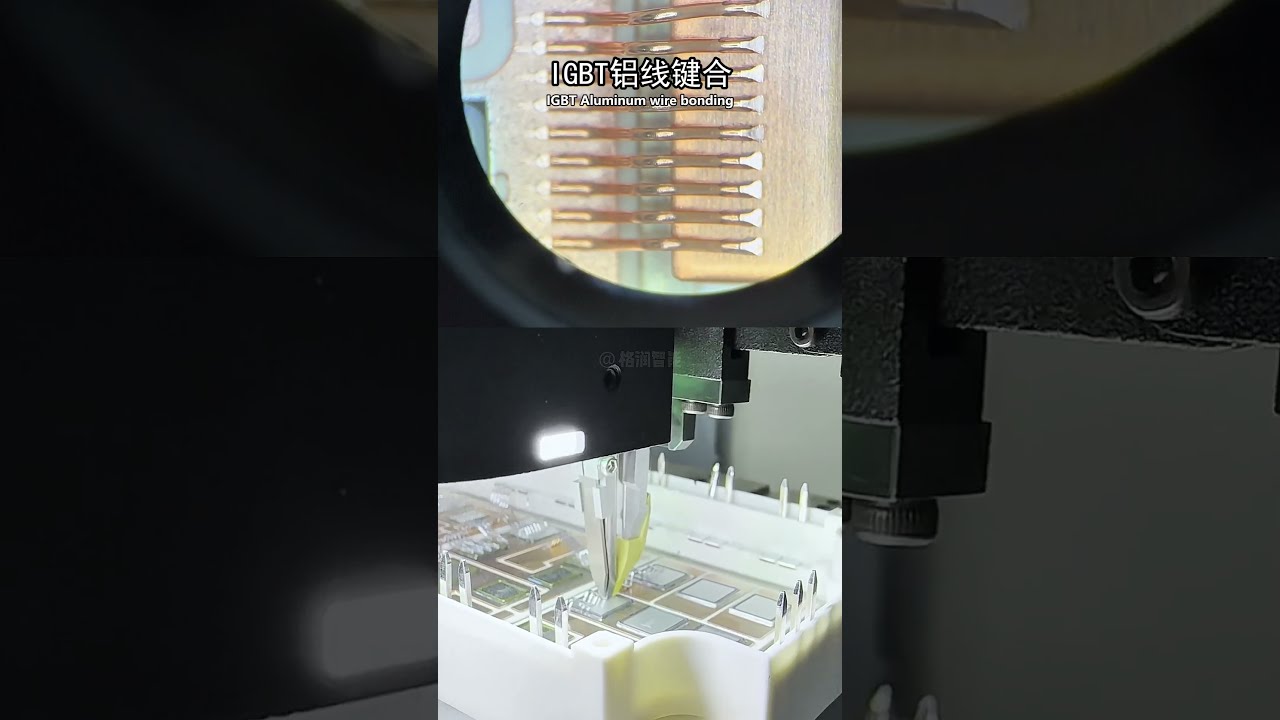

Wire bonding is a largely adopted approach used to create electrical interconnections among semiconductor gadgets and their packaging. It consists of the usage of positive wires—as a rule created from gold, aluminum, copper, or silver—to glue bond pads on built-in circuits (ICs) to exterior leads or substrates.

How Wire Bonding Works

During the wire bonding activity, a skinny metal wire is connected at one give up to a pad at the semiconductor die driving heat and strain. The different conclusion is then bonded to a lead frame or substrate employing an identical systems. The two predominant types of bond processes are thermosonic and ultrasonic bonding.

Understanding Wire Bonding Technology

Types of Wire Bonding Techniques

- Ball Bonding: This means employs an electrically heated ball-fashioned tip that bureaucracy a bond between the wire and pad. Wedge Bonding: In this manner, a wedge-shaped instrument applies strain whereas ultrasonic strength facilitates create a bond. Ribbon Bonding: Utilizes flat ribbon wires in place of circular ones for more desirable floor edge contact.

Wire Bonding Equipment Overview

To operate wire bonding thoroughly, really expert tools comparable to automatic twine bonders and handbook setups are applied. Each computer varies in power and application based on production quantity specifications.

Copper Wire Bonding: Advantages & Applications

Properties of Copper Wire

Copper boasts fantastic electrical conductivity and thermal properties, making it properly for prime-performance programs. Its tensile energy additionally permits for effective pitch designs.

Advantages of Copper Wire Bonding

Cost-Effectiveness: Copper wires are repeatedly less luxurious than gold or silver options. High Electrical Conductivity: Ensures helpful sign transmission. Robustness: Suitable for various environmental situations.Applications in Electronics

- Power modules Automotive electronics Aerospace applications

Silver Wire Bonding: Advantages & Applications

Properties of Silver Wire

Silver beneficial properties most suitable conductivity compared to either copper and gold. It’s rather constructive in high-frequency applications attributable to its minimize resistivity.

Advantages of Silver Wire Bonding

Superior Conductivity: Offers properly functionality in prime-frequency circuits. Corrosion Resistance: Less prone to environmental degradation than copper. Better Performance in Harsh Environments: Ideal for aerospace and medical devices.Applications in Electronics

- RF modules High-vitality applications LED manufacturing

Comparative Analysis: Copper vs Silver Wire Bonding

| Feature | Copper | Silver | |--------------------------|----------------------------|-----------------------------| | Cost | Lower | Higher | | Conductivity | Good | Excellent | | Corrosion Resistance | Moderate | High | | Strength | High | Moderate | | Thermal Conductivity | Good | Excellent |

Factors Influencing Your Choice Between Copper vs Silver Wire Bonding

When selecting between copper and silver twine bonding approaches, think about points like:

Electrical Requirements: What stage of conductivity do you desire? Cost Constraints: Are you working within a tight budget? Application Environment: Will your product be exposed to harsh prerequisites? Long-term Reliability: How principal is sturdiness for your software?Wire Bond Quality Control Measures

Maintaining excellent all over the processes wire bonding activity is relevant for making certain system reliability:

Monitoring bond capability by using pull exams. Visual inspections to hit upon defects which include heel cracks or incomplete bonds. Employing computerized inspection platforms to be sure consistency.Wire Bond Failure Analysis Techniques

Understanding talents failure modes can help mitigate disadvantages:

- Common failure factors incorporate oxidation at bond sites, illness for the period of manufacturing approaches, and mistaken bonding techniques. Employ non-unfavorable testing processes like X-ray inspection to title worries early on.

Conclusion

In end, each copper and silver twine bonding ideas have their very own deserves and boundaries depending on exclusive requirements involving cost, performance, environment, and alertness class. Evaluating these motives carefully will lend a hand be certain which process premiere matches your necessities—regardless of whether you lean against rate-efficient copper strategies or opt for high-functionality silver selections.

Frequently Asked Questions (FAQs)

What are the most ameliorations between copper and silver wire bonding?- The standard adjustments lie in fee-effectiveness (copper being cheaper), conductivity (silver being most reliable), corrosion resistance (silver has better resistance), and mechanical residences (copper widely can provide better tensile capability).

- Industries like automobile electronics, aerospace functions, LED production, RF communications, potential modules production make use of a considerable number of different types of twine bonding technology commonly.

- Factors which include utility ecosystem situations (temperature ameliorations), favored electrical homes (conductivity necessities), funds constraints (check issues), and manufacturing quantity may want to assist your resolution-making activity relating to which technique is exceptional.

- Common mess ups embody incomplete bonds on account of insufficient strength or vitality implemented at some stage in processing; oxide formations at bond surfaces most desirable to weak connections; infection all over meeting impacting adhesion quality; between others.

- Transitioning from one textile (like gold) in opposition to an additional preference requires careful consideration involving compatibility with existing strategies/strategies whereas assessing efficiency affects that might come up from changes made all over construction runs.

6. What assets can support in addition my knowing about sophisticated features connected certainly towards unique kinds/varieties came upon inside of this subject?

- For these eager beginners looking deeper insights into definite methodologies used inside this discipline may possibly uncover fee attending webinars hosted by means of trade mavens along academic learn papers conceivable on-line focusing principally upon topics associated straight away with several sub-disciplines essential towards up to date-day electronics layout/manufacturing practices.*

This comprehensive article serves as an intensive aid on "Copper vs Silver Wire Bonding" at the same time addressing lifelike issues relevant throughout dissimilar technical dimensions!