Introduction

In the realm of electronics, the connections made between microchips and substrates are principal. One of the maximum widespread tools for starting these connections is gold wire bonding. This methodology, many times utilized in semiconductor packaging, holds a novel function simply by its reliability and effectiveness. In this newsletter, we shall delve into the gold wire bonding task, exploring its innovations, reward, challenges, and purposes in assorted industries. Whether you’re a seasoned engineer or simply starting to study cord bonding know-how, this accomplished help will present insights that will make stronger your understanding of this crucial strategy.

What is Gold Wire Bonding?

Gold cord bonding refers to the task of connecting semiconductor contraptions riding high quality gold wires. These wires function electrical interconnections among completely different areas wedge wire bonding on a chip or between a chip and a substrate. The cord bonding process regularly comprises both ball bonding or wedge bonding programs.

The Wire Bonding Process

The twine bonding technique often incorporates quite a few steps:

Preparation of the Surface: The surfaces with the intention to be bonded will have to be fresh and unfastened from contaminants. Bonding Technique Selection: Choose between ball bond or wedge bond based totally on application standards. Wire Feeding: A skinny wire spool feeds the bonding laptop. Bond Creation: Using heat and pressure (or ultrasonic strength), bonds are created at exact places. Quality Inspection: Conduct assessments which include pull assessments to be certain bond force and first-rate.Gold Wire Bonding vs Aluminum Wire Bonding

When discussing gold twine bonding, that's main to compare it with aluminum twine bonding:

- Material Properties: Gold wires show off first-class conductivity and withstand oxidation greater than aluminum. Cost Factors: Gold is more luxurious than aluminum; notwithstanding, it's going to be offering superior functionality in high-reliability functions. Applications: Gold wire is regularly hottest in high-frequency applications by way of its awesome electric properties.

Advantages of Gold Wire Bonding

- High thermal stability Resistance to corrosion Excellent conductivity Lower chance of electromigration

Challenges in Gold Wire Bonding

While gold twine bonding has several advantages, it comes with its own set of demanding situations:

- Cost implications via gold prices Risk of over-bonding most advantageous to defects Potential environmental matters relating to gold mining

Types of Wire Bonding Techniques

Understanding the other types of cord bonding procedures is an important for selecting the properly strategy to your software:

1. Ball Bonding

This procedure makes use of a small ball shaped at the quit of the cord that creates a connection when pressed against a surface.

2. Wedge Bonding

Wedge bonding employs a flat software as opposed to a ball to create connections through setting pressure at the wire opposed to the surface.

3. Ribbon Bonding

This formula utilizes wider ribbon-like wires for creating greater bonds applicable for chronic modules.

4. Thermosonic Bonding

Combining warmth with ultrasonic electricity complements bond fine for the period of the manner.

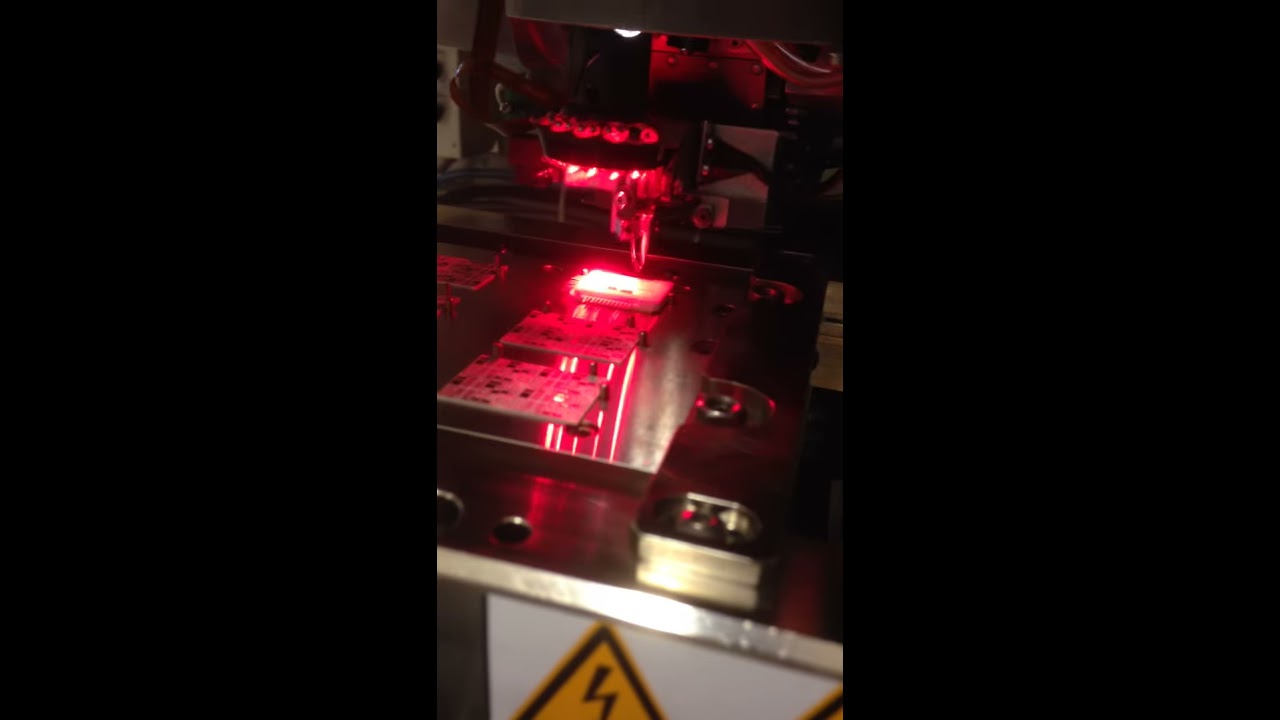

Wire Bonding Equipment and Machines

To put in force nice gold cord bonding, really expert appliance is needed:

- Wire Bonding Machines

Modern machines come competent with programmable settings that optimize parameters like temperature and tension for top management at some point of the bonding course of.

- Bonding Tools

Tools reminiscent of capillary tubes facilitate proper placement and manipulation of cord throughout the time of bonding.

Wire Bonding Applications Across Industries

Wire bonding applied sciences discover functions throughout lots of sectors:

- In Semiconductors

Used radically for connecting chips inside of ICs (Integrated Circuits).

- In Automotive Electronics

Essential for ensuring safe connections inside of vehicle electronic programs.

- In Medical Devices

Important for devices requiring prime reliability owing to life-indispensable functionalities.

- In Aerospace Applications

Ensures comfy connections beneath intense circumstances wherein reliability is paramount.

Wire Bond Failure Analysis

Understanding widely used failure modes in wire bonds is helping mitigate risks linked to failures:

Bond Lifting: Occurs while immoderate strain leads to bond detachment. Heel Cracks: Result from improper dealing with or alignment throughout the time of application. Oxidation: Can arise if wires are usually not kept adequately in the past use. Incomplete Bonds: Often as a result of inadequate rigidity or temperature settings right through program.Ensuring Wire Bond Reliability

To be sure that lengthy-term reliability in twine bonds:

Monitor environmental aspects which include humidity and temperature. Implement rigorous testing criteria inclusive of pull tests and shear assessments. Utilize acceptable cleansing techniques post-bonding to stop contamination which could end in screw ups.FAQs About Gold Wire Bonding

1. What are the foremost reward of with the aid of gold over aluminum in wire bonding?

Gold grants most popular conductivity and resistance to oxidation when compared to aluminum, making it more safe in prime-frequency programs notwithstanding being costlier.

2. How does thermosonic ball bonding vary from general methods?

Thermosonic ball bonding combines warmth with ultrasonic potential in the course of the bond advent part which improves bond strength when put next to conventional strategies that count fullyyt on mechanical strain.

3. What styles of inspections are hired in best handle for twine bonds?

Common inspections incorporate visual inspections, pull checks, shear checks, X-ray inspections, and automatic bond inspection techniques which examine both aesthetic caliber and structural integrity.

4. Can I learn about wire bonding by using on-line sources?

Yes! Many universities be offering programs on semiconductor packaging such as features like wire bonding. Online systems also host webinars and tutorials concerning this era.

five. What role does environmental handle play in positive cord bonding?

Controlling environmental reasons comparable to humidity can critically have an impact on bond pleasant; severe moisture can cause oxidation which weakens bonds through the years.

6. Is there any ongoing learn into new resources for advanced reliability?

Yes! Researchers are exploring opportunities like copper attributable to its cost-effectiveness at the same time as investigating coatings or healing procedures that give a boost to its efficiency characteristics rather like these visible in gold wiring purposes.

Conclusion

Gold Wire Bonding represents an important expertise inside electronics manufacturing that mixes potency with reliability across a number purposes—from customer instruments all the way up with the aid of difficult aerospace additives. While it gives yes demanding situations—comparable to bigger material expenditures—its merits usally outweigh these troubles whilst enthusiastic about long-term overall performance necessities above all inside principal procedures where failure isn't very an option! Understanding both processes involved which includes quality practices ensures best outcomes no matter if one is calling at essential circuit forums or advanced integrated circuits packed densely collectively inner progressive electronics lately!

This substantial exploration into "Gold Wire Bonding: Techniques, Benefits, and Challenges" can provide crucial insights into now not merely how this technological know-how operates however why it is still so indispensable throughout distinct industries these days!