Introduction

In the world of electronics, the cord bonding strategy stands as a most important method for establishing electric connections among semiconductor contraptions. Whether it’s for integrated circuits (ICs), microcontrollers, or sophisticated potential modules, wire bonding generation performs a serious function in making certain reliability and efficiency. As electronics proceed to lessen in length while expanding in complexity, suggestions in skinny and thick twine bonding strategies are getting a growing number of correct.

Wire bonding equipment may be largely labeled into a few forms, adding ball bonding, wedge bonding, ribbon bonding, and their variants. Each means has its exclusive purposes and reward depending on factors just like the substances used, environmental conditions, and tool performance. In this text, we delve into the resourceful developments in either skinny and thick wire bonding methods that are shaping the long term of semiconductor production.

What is Wire Bonding?

The twine bonding process is a means used to attach two electronic accessories driving satisfactory wires made from material like gold, aluminum, copper, or silver. This system is simple for developing the interconnections wished for contraptions to role thoroughly.

How Wire Bonding Works

At its core, cord bonding comprises quite a few steps:

Preparation: The floor of the semiconductor chip must be wiped clean and well prepared for bonding. Placement: A small twine is hooked up to the bond pad at the chip employing either warm or ultrasonic vigour. Formation: The twine is then looped to succeed in another bond pad or substrate the place it is going to be connected. Bond Creation: The remaining step involves applying power and warmth (or sonic power) to create a reliable mechanical and electric connection.Types of Wire Bonding

Understanding loads of styles of cord bonding helps producers settle upon the properly process for his or her targeted packages:

- Ball Bonding: Utilizes a small ball shaped at the finish of a wire that bonds to the chip’s pad. Wedge Bonding: Employs a wedge-shaped instrument that compresses in opposition t equally surfaces. Ribbon Bonding: Involves wider ribbons of metal used notably in top-vigor packages.

Innovations in Thin Wire Bonding Techniques

Advantages of Thin Wire Bonding

Thin wire bonding can supply countless benefits:

Space Efficiency: Reduced dimension allows greater elements on a single chip. Improved Performance: Lower inductance paths end in higher sign integrity. Cost-Effectiveness: Less textile usage interprets into scale back bills.Materials Used in Thin Wire Bonding

Thin wires are customarily product of:

- Gold: Known for its astounding conductivity however will be highly-priced. Aluminum: A expense-helpful opportunity with respectable conductivity. Copper: Offers top conductivity but requires cautious coping with with the aid of oxidation issues.

Emerging Technologies in Thin Wire Bonding

Recent advancements include:

- Increased automation within skinny twine bonding machines for precision. Enhanced manage tactics that permit for real-time differences all over the bonding job.

Table 1: Comparison of Thin Wire Materials

| Material | Conductivity | Cost | Applications | |-------------|--------------|-------------|------------------------| | Gold | Excellent | High | High-performance ICs | | Aluminum | Good | Medium | General electronics | | Copper | Very Good | Low | Budget-touchy designs |

Innovations in Thick Wire Bonding Techniques

Overview of Thick Wire Bonding Process

Thick wire bonding commonly makes use of higher diameter wires (many times improved than zero.8 mm) good for high-recent packages equivalent to capability amplifiers or potential modules.

Benefits of Using Thick Wires

Higher Current Capacity: Ideal for pressure electronics requiring immense modern circulation. Robustness: Thicker wires supply mechanical balance against vibration and thermal stresses.New Developments in Thick Wire Binding Technologies

Recent thoughts comprise:

- Advanced thermal control systems integrated into thick wire bonds that raise reliability less than strain situations. Enhanced checking out methodologies geared toward recovering first-rate manage for the duration of manufacturing techniques.

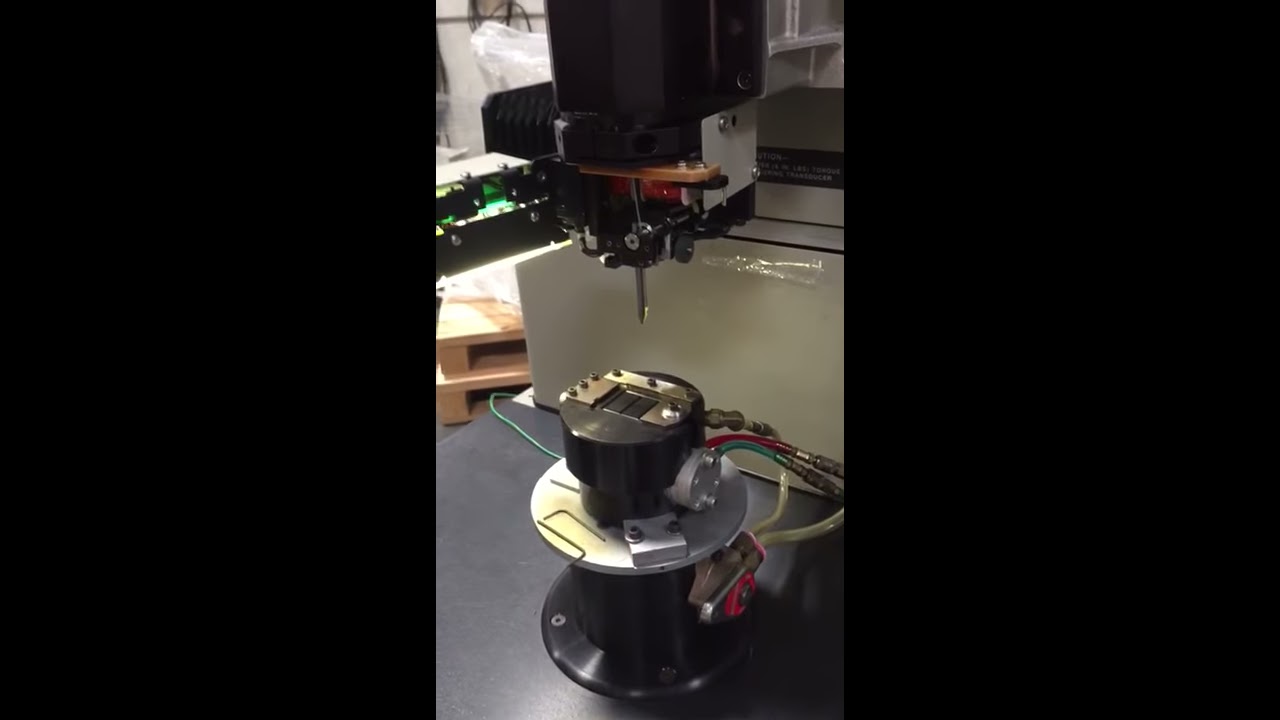

Wire Bonding Machine Technologies

Types of Wire Bonding Machines

Selecting the precise computer is quintessential based on your program needs:

Manual Machines: Suitable for low-extent manufacturing however require knowledgeable operators. Semi-Automatic Machines: Offer more suitable effectivity at the same time nevertheless needing some human intervention. Fully Automatic Machines: Ideal for excessive-volume construction with regular satisfactory output.Features to Consider When Choosing a Machine

When selecting a cord bonding machine, do not forget causes like speed, accuracy, ease of use, and preservation requirements.

Table 2: Comparison of Machine Types

| Type | Speed | Accuracy | Maintenance | |--------------------|---------|------------|--------------| | Manual | Low | Moderate | High | | Semi-Automatic | Medium | High | Medium | | Fully Automatic | Very High| Very High | Low |

Wire Bonding Applications Across Industries

Wire bonding technology reveals big application across numerous sectors:

1. Electronics Industry

Used predominantly in IC packaging and circuit board meeting.

2. Automotive Electronics

Critical for guaranteeing official connections inside automobile regulate models.

three. Aerospace Applications

Employed in radar programs and satellite communications where reliability is paramount.

4. Medical Devices

Essential for scientific gadget in which overall performance can influence patient safeguard at once.

Wire Bonding Failure Analysis

Understanding doable failure modes is relevant to enhance reliability results:

Common Failure Modes

Some conventional considerations incorporate:

Bond Lifting: Often due to negative floor instruction or severe heat in the course of bonding. Heel Crack: Can show up attributable to mechanical stresses post-bond formation. Oxidation: Leads to bad electrical overall performance if no longer managed right.Frequently Asked Questions (FAQs)

li26/ol6/li27li27/ol7li28# How does temperature affect the wire bonding system?- Temperature plays a severe role; too top could motive degradation at the same time as too low can bring about incomplete bonds.

- Automated machines present consistency and pace which are necessary for vast-scale production runs.

- Your resolution need to depend upon causes together with space constraints, required existing skill, and layout specifications.

Conclusion

The techniques in skinny and thick twine bonding options preserve to drive advancements throughout distinct industries—from patron electronics to aerospace applications—ensuring physically powerful connections that preserve modern day digital instruments' growing demands for pace and efficiency. By realizing these equipment' intricacies—such as their respective merits, demanding situations, doable failure modes—and leveraging today's equipment tailored in particular closer to these approaches—engineers can be certain that they harness highest functionality when minimizing expenses associated with failures or defects.

In this exploration of "Innovations in Thin and Thick Wire Bonding Techniques," we have exposed how fundamental these tactics are inside of state-of-the-art fast-paced technological panorama while highlighting key components which includes material selection nuances thru true-international examples—all supposed in the direction of empowering engineers with abilities critical not on the subject More help of what exists at this time however also what is likely the next day!