Introduction

In the ever-evolving international of electronics, the call for for professional connections is paramount. One of the quintessential processes in attaining this can be cord bonding, exceedingly as a result of ultrasonic wedge bonding. But what precisely is ultrasonic wedge bonding? How does it paintings, and what advantages does it provide over different cord bonding tips? This entire publication will delve deep into ultrasonic wedge bonding, exploring its methods, merits, purposes, and far extra. With a focus on the nuances of the wire bonding system, we target to offer insights into why this technology has come to be an business accepted.

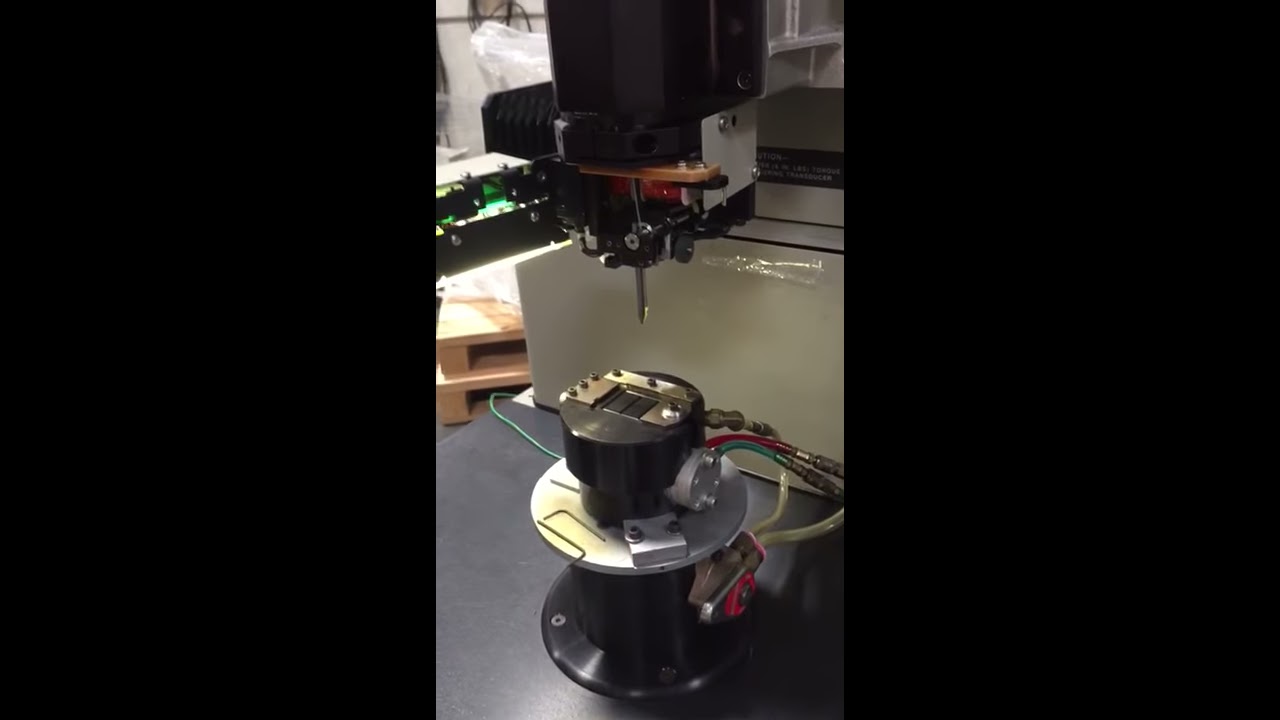

What is Ultrasonic Wedge Bonding?

Ultrasonic wedge bonding is a particular sort of cord bonding strategy that makes use of ultrasonic electricity to create reliable steel-to-steel bonds between wires and semiconductor units. This formula employs a wedge-formed tool that applies force although supplying ultrasonic vibrations to facilitate the bond formation at scale down temperatures when put next to conventional equipment.

The merits of this procedure consist of diminished thermal tension on materials and progressed bond reliability. Furthermore, it permits for the usage of countless elements like gold, aluminum, copper, and silver aluminum wire bonding for wire bonding programs in semiconductors.

How Ultrasonic Wedge Bonding Works

To take into account how ultrasonic wedge bonding works, let’s spoil down the course of:

Preparation: The surfaces to be bonded are cleaned and willing. This step guarantees optimum adhesion among the substances in touch. Placement: A thin wire (continuously gold or aluminum) is fed into the wedge bonder device. Wedge Tool Function: The wedge software descends onto the substrate the place the bond is to be fashioned. Ultrasonic Energy Application: Ultrasonic vibrations are utilized when asserting rigidity through the wedge device. Bond Formation: The aggregate of power and ultrasonic power reasons localized heating at the interface, resulting in a metallurgical bond.This system is pretty handy in programs wherein precision and reliability are severe—assume semiconductors or microelectronics.

Key Advantages of Ultrasonic Wedge Bonding

1. High Reliability

One sizeable benefit of ultrasonic wedge bonding is its top reliability due to reduced thermal pressure for the time of the bonding method. This characteristic makes it correct for delicate digital system that is not going to resist excessive temperatures.

2. Material Versatility

Ultrasonic wedge bonding helps many different resources—gold wires for top conductivity packages or aluminum wires for fee-superb solutions—making it versatile across special industries.

3. Cost-Effectiveness

Compared to other cord bonding processes like ball bonding or soldering, ultrasonic wedge bonding can cut down manufacturing expenditures by using minimizing cloth waste and enhancing yield prices.

four. Small Footprint

The compact nature of ultrasonic wedge bonders allows them to are compatible quickly inside of automated production lines without requiring giant redesigns.

5. Enhanced Performance

With improvements in ultrasonic know-how, latest machines offer progressed manage over parameters inclusive of chronic settings and drive calibration—additional bettering bond first-class.

6. Environmentally Friendly

By making use of much less warmness in the course of processing, ultrasonic wedge bonding reduces potential intake—a key point in today’s environmentally aware manufacturing panorama.

Types of Wire Bonding Processes

Wire bonding tactics range primarily based on program necessities and parts being used:

- Ball Bonding: Utilizes a ball formation at the tip of a cord. Wedge Bonding: Employs a flat or cylindrical device for developing bonds. Ribbon Bonding: Uses wider ribbons as opposed to around wires. Thermosonic Bonding: Combines warm with ultrasonic energy—leading for bound fabrics.

Understanding those distinctions allows manufacturers select the so much suited system established on their detailed necessities.

Common Wire Bonding Techniques

When discussing cord bonding technologies, a number of methods stand out:

Ultrasonic Wire Bonding: Focuses on through sound waves for the time of the welding strategy. Thermosonic Wire Bonding: Applies warmness inclusive of ultrasound for valuable bonds. Manual vs Automatic Wire Bonding: Manual ways is also slower yet allow for superior manage; automated platforms make stronger throughput considerably. Deep Access Wedge Bonding: Designed especially for difficult geometries the place natural gear might warfare. Hybrid Wire Bonding Techniques: Combining varied tactics can bring about optimized results tailor-made to precise functions.These methodologies assist be certain that manufacturers can reach preferred effects stylish on their operational constraints.

Applications of Ultrasonic Wedge Bonding

The versatility of ultrasonic wedge bonding way it reveals program across diverse sectors:

- Semiconductors: Essential in chip packaging the place reliability is crucial. Automotive Electronics: Used in significant platforms like airbags or engine controls wherein failure isn’t an preference. Medical Devices: Ensures robust connections in devices which includes pacemakers or diagnostic package. Telecommunications: Widely hired in RF module assemblies wherein sign integrity matters largely.

Understanding these purposes highlights simply how quintessential this era has turn into in complex production approaches.

Wire Bond Quality Control

Quality control plays a pivotal function in ensuring triumphant production tactics:

Regular inspection protocols have to be widely used—these may well embrace X-ray inspection or computerized visible assessments. Implement pull assessments or shear tests to validate bond power lower than various situations. Maintain documentation outlining specifications set with the aid of businesses like JEDEC for constant performance overview in opposition t benchmarks. Continuous practise courses make certain operators remain updated with absolute best practices involving kit utilization and renovation procedures.Incorporating these measures promises most popular functionality from both operators and machines alike across creation cycles.

FAQ Section

What Are Common Materials Used in Ultrasonic Wedge Bonding?

Gold, aluminum, copper, and silver are in the main applied by reason of their conductive homes; though, gold stays widespread due in large part due its top-quality conductivity regardless of increased prices associated with sourcing it when compared to choices like aluminum or copper wiring chances which may well supply payment reward based upon application necessities!

How Do Ultrasonic Settings Affect Quality?

Setting inappropriate parameters can end in vulnerable bonds characterised by means of defects resembling heel cracks or illness worries; for that reason cautious calibration may want to appear prior to taking off any jobs involving necessary system!

What Is The Typical Cost Range For A Wire Bonder Machine?

Prices can fluctuate extensively based totally on elements specific however most commonly latitude at any place from $20k-$200k relying upon standards required adding automation ranges desired!

Can I Use My Existing Equipment For Ultrasonic Wedge Bonds?

While some latest setups might also accommodate enhancements allowing integration with new gear designed principally round ultrasonics—we suggest consulting with package companies previous making changes when you consider that compatibility varies greatly!

How Long Does An Average Ultrasonic Wedge Process Take?

Typically finished within milliseconds once all parameters have been set efficaciously—despite the fact genuine cycle instances count number seriously upon components such as ingredient sizes interested & wide variety being processed simultaneously!

Is Training Required For Operators Using This Technology?

Yes! Training guarantees adherence no longer most effective protection precautions however also maximizes effectivity gains practicable due to desirable utilization most competitive practices pertaining methods operation & renovation schedules!

Conclusion

Ultrasonic wedge bonding represents a extensive development within cord-bonded semiconductor fabrication procedures—supplying unprecedented reliability at aggressive rates even though accommodating distinctive subject material possibilities suited across distinct industries! By expertise its intricacies—from center ideas governing the way it works through useful purposes determined at some stage in present day electronics manufacturing—you’ll advantage worthwhile insights enabling informed selection-making involving future investments within this quintessential zone!

The ongoing evolution surrounding those applied sciences grants wonderful developments ahead; as a consequence staying educated approximately emerging tendencies will serve companies well as they navigate demanding situations supplied by increasingly tricky needs faced day by day!